It can be confusing to differentiate Lag screws from Lag bolts. If you're confused about the difference between a lag screw and a lag bolt, we have researched this topic for your convenience. Here's what we found below!

Essentially, there's no distinction between these two terms in usage. In both cases, the lag screw and lag bolt function the same. Although technically, it is more adept at describing lags as screws rather than bolts.

In the following sections, we'll discuss the difference between a bolt and a screw, how a lag bolt/screw functions, and why a lag screw is a technically correct term. We'll also share the types of lag screws and where they are typically used, so keep reading!

What Do You Use A Lag Screw For?

You often use lag screws to connect heavy lumber or other materials that support a significant weight.

These screws are often found on certain parts of your house, such as porch swings, patios, entertainment areas, decks, roof beams, and your structure's general framing.

You can use lag screws to fasten decking panels to the ground and connect the structural members to the panels. Additionally, the strength of a roof beam is crucial to a building's structural integrity.

To give a roof the necessary strength, lag screws are frequently employed.

You can also use them in your home's structural framing, which could involve installing joists, joining a patio, or even building stud walls.

What Do Lag Screws Differ From Other Screw Types?

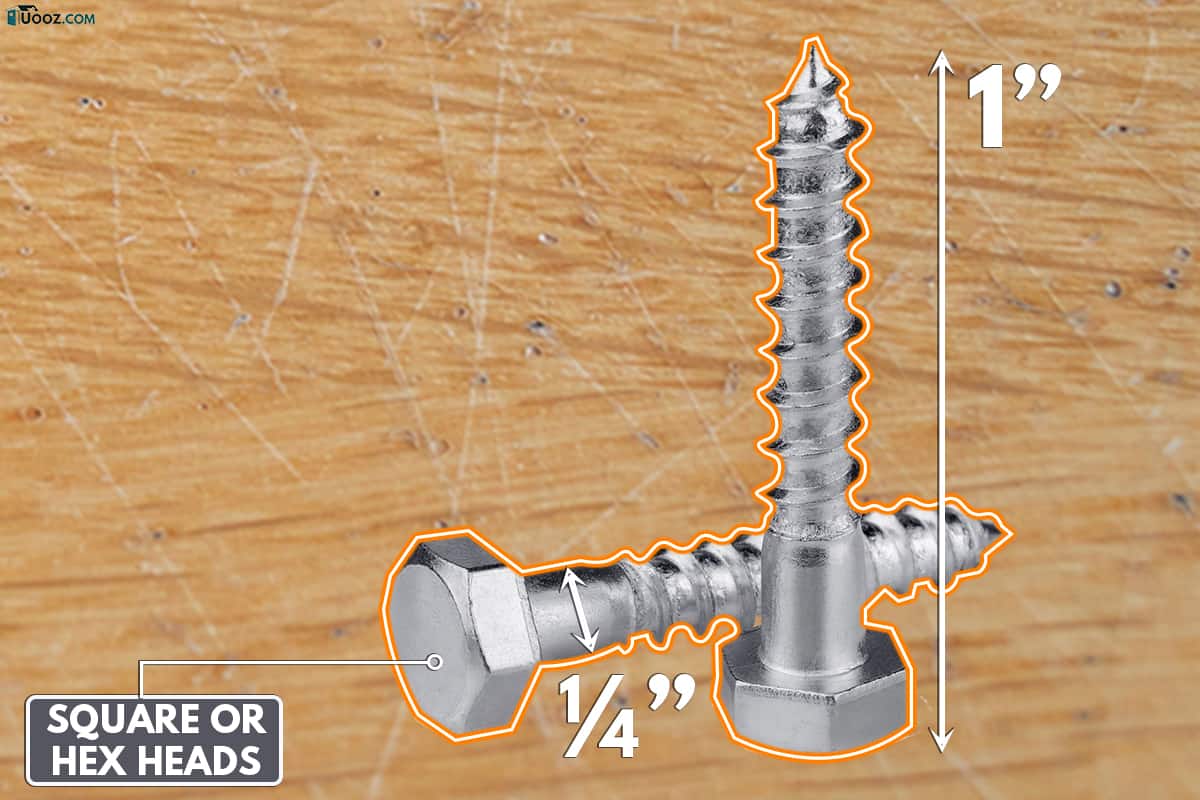

Compared to other screws, lag screws are unique. They are bigger in comparison to the majority of common screws. Typically, the minimum length of a lag screw is 1" with a thickness of 1/4".

Additionally, drilling pilot holes is necessary to prevent splitting the wood or damaging the screw. This is also to make the installation simpler and faster.

Comparatively, other screws have a variety of head types, but lag screws only have square or hex heads. This is because lag screws require high torque. You should use ratchets or nut drivers to drive in lag screws.

How To Properly Install A Lag Screw

- Align the materials you'll connect. Clamp them together to secure the materials in place.

- Mark the spots where you want to place the pilot holes for your lag screws. You can use a pencil or a marker for this.

- After securing the materials in place, drill the pilot holes. Use a smaller bit diameter than your screw's diameter. Lag screws are more effective when the pilot hole is smaller. A general guideline you can follow is 1/3 of the length of your screw should be the depth of your pilot hole.

- Tighten the lag screws with a ratchet. Please continue to do so until they're flat with the material.

- You can remove the clamp after ensuring the connection is tight and secure.

Click here for this electric ratchet on Amazon.

One additional tip, it is advisable to install a lag screw all at once. Doing this, the screw won't wiggle around too much and avoids splitting the material.

Bolt Vs. Screw: What's The Difference?

In this section, we'll compare the differences between a bolt and a screw in terms of the fastening method, thread pattern & shape, strength, and cost.

Fastening Method

The most apparent difference between a bolt and a screw is how they should be installed.

Bolts are usually partnered with a nut and washer. They are installed by pushing them through the material, instead of being hole-tapped, and then locked with a nut at the back.

You need to use a wrench or spanner to tighten the nut to the bolt.

Click here for this wrench on Amazon.

On the other hand, screws are typically placed into tapped holes. There are also self-tapping screws that produce their thread.

Screwdrivers are the most commonly used tool to drive screws to holes and tighten them. However, power drills are also used to drill pilot holes. Nuts are not necessary if you use screws.

Click here for this electric drill on Amazon.

Thread Pattern & Shape

Bolts have threads that do not go up to their heads. That's why they are often called half-thread. Comparatively, screws are fully threaded up to their heads.

Bolt threads are also spiral-shaped, while screw threads are helical.

Strength

In terms of holding power, bolts offer the strongest gripping force compared to other fasteners.

Aside from the threads and nuts holding them in place, the washer also aids in distributing the load over a broader surface area, making them less prone to wear and tear and lessening the possibility of the bolts loosening over time.

Cost

Bolts are more expensive than screws because of the nuts and bolts sold with them. Of course, bolts use more metals in their production. They also take up a little more room in storage, which impacts the cost.

Why Do You Call It A Lag Screw?

From the definition of a bolt and a screw mentioned in the previous section, the technically correct term would be a lag screw.

What Are The Different Types Of Lag Screws?

Lag screws are available in a wide range of diameters and forms. There are different types of lag screws based on their head shapes and coatings.

Based On Head Shapes

- Square Head Lag Screws- This type is frequently used to have a more classic appearance.

- Hex Head Lag Screws- In contrast to square heads, hex heads give a more contemporary style to your construction design.

Based On Coatings

Zinc Lag Screws

Usually, interior applications demand zinc screws. Plain zinc lag screws are more difficult to locate and less common than the other varieties.

Click here for this product on Amazon.

Galvanized Lag Screws

These are the most popular and least expensive types of lag screws. They are excellent for pressure-treated lumber and outdoor use because of their corrosion resistance.

Click here for this product on Amazon.

Stainless Steel Lag Screws

Because of the strength of this type of lag screw, they are among the most widely used.

These are frequently used in outdoor and marine applications such as the development of docks and oceanfront areas.

Click here for this product on Amazon.

Silicone Bronze Lag Screws

This copper alloy, used in constructing wooden boats, is stronger and more corrosion-resistant than brass.

These screws are nonetheless quite effective in fastening materials, despite bronze's softer nature compared to stainless steel.

Click here for this product on Amazon.

How Strong Are Lag Screws?

Lag screws can support heavy weights because of their size. They are the go-to fasteners for many structural construction projects because of their extreme strength.

The screw is stronger and can withstand greater weight when it has a wider diameter- up to 9 times more weight on wood than a standard nail. However, consulting with a qualified expert is imperative before beginning any structural work.

Additionally, a 5/16" diameter lag screw can support a 212 to 307 pounds load, depending on the type of wood it's fastened to.

Are Structural Screws A Better Alternative To Lag Screws?

Yes, they are. Lag screws are widely used because of their adaptability and availability. But structural screws are steadily and gradually taking their place.

These are some reasons why structural screws can be an alternative to lag screws:

- They are simpler and more effective to use.

- They are composed of solid, heat-treated steel.

- These screws are substantially smaller but can support the amount of load or more than standard lag screws.

- Most structural screws don't need to be pre-drilled. So it only takes a short time to finish fastening your project's materials.

- They also meet strict requirements for suitability with treated wood and construction projects.

- The maximum shear for structural screws ranges from 250 to 400 pounds.

Despite their apparent advantages, structural screws have a few drawbacks: cost and limited availability.

Structural screws are three times more expensive than lag screws, making this its major disadvantage.

The choice of structural screws is another problem. Although vendors frequently offer an extensive range of sizes, they could only have one or two types of screws, which might be excessively restrictive.

To Finish Up

Don't be confused about whether to use the term lag bolt or lag screw. These terms essentially refer to the same thing. However, the more technically correct term is a 'lag screw.'

To know the difference between a bolt and a screw, the most obvious thing to look at is the thread pattern and shape.

Most times, the thread of bolts doesn't go all the way up to its head, unlike screws. Additionally, the thread shape of bolts is spiral, while that of a screw is helical.

While we have your attention, check out these related screw posts!