Screwing in the stripped screw may seem not ideal but still wondering how to deal with it? You've come to the right place because we looked into this topic to help you and here is what we discovered.

You can use any of the following strategies to screw in a stripped screw:

- Filling the recess with rubber bands.

- Using a screw extractor in reverse.

- Creating a new drive recess.

- Tapping the screw directly using a hammer.

We'll go into great detail about each of the aforementioned strategies in this article. Additionally, we'll show you how to get rid of these stripped screws if necessary. So keep reading.

How To Screw In A Stripped Screw?

A screw is a type of threaded fastener used to attach objects or support their stability in place. The majority of screws have a head made to suit a specific kind of screwdriver, enabling users to insert or remove the screw.

However, a stripped screw is one that can't be turned using standard techniques because the head has been destroyed. This may develop as a result of normal wear and tear or from using the incorrect screwdriver type or worse using an electric screwdriver as it can damage the head more quickly.

Few jobs in the project might halt just only because of a stripped screw. These screws are not only difficult to remove with a standard screwdriver, but also impossible to tighten.

That is why it is much preferable to just purchase a new screw than to attempt to screw in one that has a stripped drive since you will later regret yourself if you decide to remove it.

Although the situation may appear hopeless, there are still tools that can turn things around if these kinds of screws are suitable for the task you have. Below are some of the techniques you may try on:

Filling The Recess With Rubber Bands

Try this first before attempting any other strategies. Over the stripped screw, place a rubber band. It works well to use wider rubber bands to provide the driver with a bit of extra grip on the stripped screw.

Click here to see this rubber band on Amazon.

Insert the tip of your screwdriver firmly, then remove the fastening slowly. The rubber band allows you to twist the screw with your screwdriver more easily.

Click here to see this screwdriver kit on Amazon.

When employing this technique, prepare to use a few rubber bands because they frequently snap under the screwdriver's pressure. You may also use a drill instead of a screwdriver to finish the job faster.

Click here to see this drill on Amazon.

Using A Screw Extractor In Reverse

If the stripped screw is adequate for the job but cannot be tightened as required, seating the screw flush using a screw extractor in reverse might work.

Click here to see this screw extractor on Amazon.

You might need to precisely mark the screw head's center using the center punch and hammer if it is totally damaged. When using the screw extractor, always refer first to its manual for proper usage of this tool.

Click here to see this center punch on Amazon.

Utilizing the proper drill bit, drill a hole through the specified punch point at the depth advised by the manufacturer. This serves as a small pilot hole for your stripped screw.

Next, insert the extractor into the tap wrench's tip. Put the extractor's tip into the drilled hole of the screw's head. Then, turn the tap wrench in a clockwise direction. Hammer the wrench until the screw is flush with the material.

Click here to see this tap wrench on Amazon.

Creating A New Drive Recess

Stripped screws may need to widen the groove of it to provide a better grip when screwing it in. You may use a thin file to open or cut the screw’s head a bit. Alternatively, you can use a Dremel at a slow speed too.

Click here to see this mini file set on Amazon.

Click here to see this Dremel tool kit on Amazon.

However, you'll need a way to strongly hold the screw while doing this, a workbench vise might be a good option. Additionally, before making any new drive recess, you should think about the type of screwdriver you have so that it won't be difficult to screw it in later on.

Click here to see this vise on Amazon.

Tapping The Screw Directly Using A Hammer

This is the last-ditch effort you may try if you really want to screw in those annoying stripped screws. Grip the hammer’s handle and start smashing the screws. Start with a light force until the screw is in place, then you can increase the force to drive the screw the rest of the way in.

Click here to see this hammer on Amazon.

However, doing so might cause some type of screw to rip a hole big enough for it to effortlessly pop out again or even shatter and have the board split. You might be able to bang it in place but it could possibly won’t be secure firmly enough to hold any weight.

How To Remove A Stripped Screw?

If screwing it in doesn't work, your only option is to remove it and get a new one. Although a stripped screw in metal or wood that won't budge may seem permanently locked, there are still many techniques you can attempt and these are the following:

Utilizing A Stripped Screw Extractor

You might only need a certain pair of stripped screw extractors if your tasks commonly involve stripped screws. These drill attachments come in a variety of shapes and sizes, and using them involves two processes.

Drill a hole in the screw's head first, then remove the screw with an extractor. This is not the same as the previously mentioned screw extractor technique because you will use it as its name implies and not in reverse.

Using Rubber Band Technique

This is the same process mentioned above on screwing in a stripped screw. The only difference is the rotational direction of the screwdriver that you will use. At this point, you only have to firmly press down your screwdriver and attempt rotating it counterclockwise.

Try using a screwdriver with a little larger head so it catches better if the screw still won't budge. Rubber bands also provide a non-slip surface that prevents your screwdriver from moving around on the stripped screw.

Try To Use Different Screwdrivers

A screwdriver of a different size or design may have a greater grip. Choose a screwdriver with a little larger bit if you're attempting to remove a stripped Phillips-head screw. Firmly press down until the screwdriver catches on the stripped head, then attempt to release the screw as usual.

Change to a flathead screwdriver if that doesn't work because it can fit into the slots better. However, if any different screwdriver doesn't help then better give up on trying it to avoid further damaging the screw.

Click here to see this flathead screwdriver on Amazon.

Cover The Screw With Duct Tape

You might get more friction from the duct tape, giving you a firmer hold on your screwdriver as you turn it into the screw. So cover the stripped screw with some duct tape. Try rotating the screw counterclockwise with your screwdriver to loosen it.

Click here to see this duct tape on Amazon.

Using Pliers To Grasp A Protruding Screw Head

It will be simpler to turn the screw if you pinch its sides. Hold the screw sides firmly with pliers and keep it rotating counterclockwise till you can remove it but be careful that your pliers don't come off. For your pliers to stay on more securely, try filing the screw's sides a little flatter.

Click here to see this pair of pliers set on Amazon.

Drilling The Screw With A Left-Handed Bit

Turning to the left typically releases common screws. The less frequent left-handed drill bit has flutes that rotate in counterclockwise.

Click here to see this left-handed bit set on Amazon.

A stripped screw may be more easily unfastened by the torque of a left-handed drill bit than by a right-handed bit. However, the drill needs to be set to reverse for it to operate.

Put Friction Drops On The Screw

For simpler screwdriver gripping, you may add friction drops to give. As soon as you have placed your screwdriver into the slot, place 1 to 2 drops into the center of the stripped screw.

Click here to see this friction drop on Amazon.

Simply rotate counterclockwise the screwdriver to loosen and remove the screw since the drops cover the space between your tool and the metal screw.

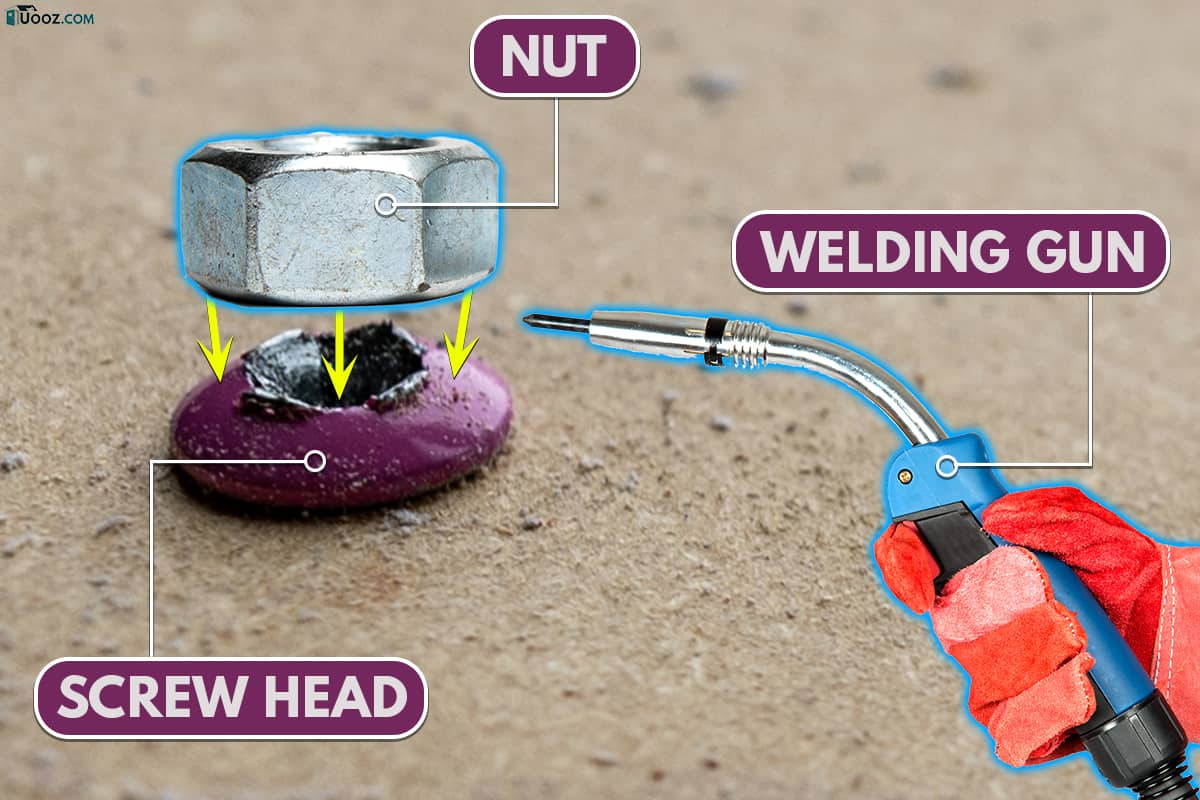

Spot-Weld A Nut Into Screw’s Head

If you're skilled with welding and have the required tools on hand, you can spot-weld a nut to the top of the screw head. By adding a nut, you can use a wrench to hold the screw. Use a nut that is roughly the same diameter as the screw head.

Hold the nut against the screw head and begin fusing the nut's bottom to the screw head. Once the nut is fastened, all you need to do to remove it entirely is grab it with a wrench and crank it counterclockwise. Just take precautions while welding, and if possible, wear the proper protective gear.

Below is a video from YouTube showing some procedures mentioned above.

Conclusion

With all these suggestions above, you can be confident that the next time you screw in or work with a stripped screw, it won't be the end of the world—it will just be another easily fixable problem. Plan accordingly because this task can take some time. Avoid hurrying the process to prevent damaging your project.

Check out other topics we have below.