Do you have gaps around your copper pipes that need to be filled and sealed? You've come to the right page. We'll help you address this issue with the best recommendations from our experts.

You can use Flex Seal, expanding foam, or silicone sealant to fill and seal the gaps and cracks around your copper pipes. These products will effectively fill up the space in between your pipes and walls to ensure that no water, air, moisture, and small insects can get in.

Keep reading so that we can fill you in with more tips and recommendations on how to fix those holes and cracks. We'll also teach you how to solder a leaking copper pipe. Let's also discuss the life expectancy of copper plumbing and if plumbers still use copper pipes to this day.

Closing gaps around pipes

Gaps around your copper pipes can invite bugs and critters inside your house. It can also cause drafts to come in, reducing the energy efficiency of your home. That's why it is to your advantage to fill those gaps and seal them as soon as possible.

Good thing there are easy solutions out there for you to fix this issue. You can use Flex Seal, expanding foam, and silicone sealant to close off the gaps.

Can you put Flex Seal on copper pipe?

Flex Seal is liquid rubber in a can. It is a rubberized spray that's used as a sealant and for fixing leaks. It is very easy to use. You just spray it on the surface that needs fixing, and it does the job of filling the holes and cracks wherever you point it toward. As it dries, it forms into a rubbery substance that effectively blocks out moisture, air, and water.

According to the manufacturers, Flex Seal can be applied on various surfaces, including copper. What's even great about this product is that it can withstand extreme temperatures ranging from -20 to 140 degrees Fahrenheit once applied on the surface. You can also paint over the rubber material if you want to make it match the color of your wall or pipe.

Click this link to find this product on Amazon.

Can you put expanding foam around copper pipes?

Another product that you can use to effectively fill gaps around your copper pipes is the expanding foam. This is a spray foam in a can that contains isocyanate and polyol resin.

When these chemicals mix with each other, they form foam. What starts as a thin liquid foam can expand up to 30 to 60 times; that's why it is able to fill the gaps and cracks along the surface and help in insulation. However, it is only recommended to use for gaps up to one inch in size.

Expanding foam adheres to surfaces made of copper quite well. In an online forum of plumbers, one participant even mentioned that he used an expanding foam 30 years ago and got to renovate the same house again. He saw for himself how the foam was still intact around the copper pipes after all these years!

Check out this product on Amazon.

What is the best sealant for copper pipes?

Experts say that the best sealant to use for copper is one that's made of silicone. It can be used for caulking to seal the gaps between the pipes and your wall.

However, they will only work on small gaps with a size of less than 1/4-inch. Silicone caulking also comes in various strengths, so choose one that is appropriate for your copper plumbing repair.

Find this silicone sealant on Amazon.

Can you solder a leaking copper pipe?

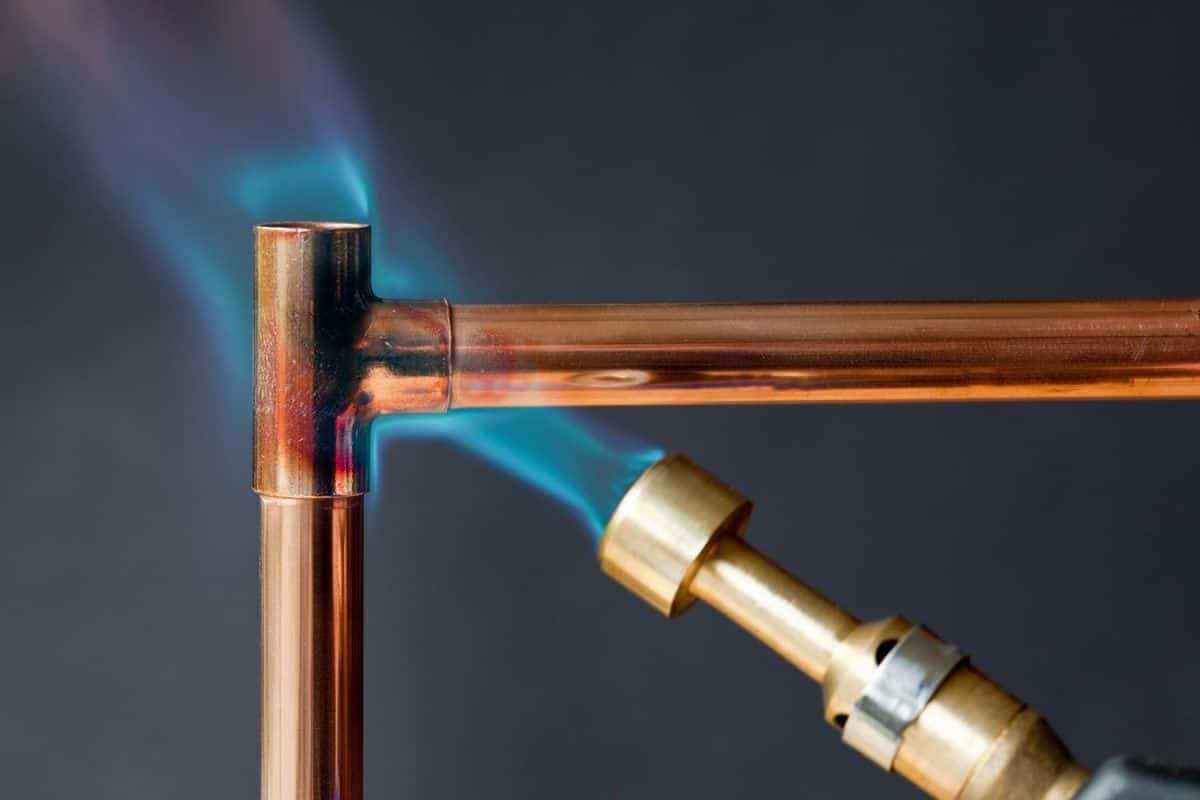

Soldering is the process of joining two or more metals together. Solder, a metal that has a low melting point, is used as a filler. As it melts with the application of heat, it mixes with the other metals and fills the hole or gap between them.

When it comes to fixing a leak on your copper pipes, you can solder them to close off the hole. However, you have to make sure that the pipe is completely drained of water before you begin. When there's water in the pipe, the heat will just be used up for steaming the water and not for melting the solder, which is a complete waste of effort.

Here's how you can solder your copper pipes:

- After draining the leaking pipe, dry and clean its outer surface using a cloth.

- Sand off the areas showing signs of corrosion.

- Wrap a wet cloth or towel around adjacent joints that don't need soldering. The wet cloth will act as a barrier and absorb the heat so that other portions of the pipe won't melt.

- Apply soldering flux or a cleaning agent to the whole joint that you're working on.

- Use a soldering iron or torch to apply heat to the affected area until the old metal melts.

- Add new solder to the surface and apply heat once more until a shiny ring forms all around the copper joint.

- Let it cool for about five minutes before you turn the water on to check if the leak stopped.

If there's still a leak, add more solder to the fitting. Hopefully, this will finally put a stop to the problem.

Do plumbers still use copper pipes?

Plumbers still use copper pipes for residential plumbing because of their durability. They are very familiar with this material which makes it easier for them to use it and conduct repairs when needed.

But copper is no longer the leading choice when it comes to water pipes. The introduction of PEX plumbing tubes has presented plumbers with a suitable alternative to copper.

PEX Tubing - The New Copper Alternative

PEX or cross-linked polyethylene flexible tubing is durable and can most probably last as long as copper pipes. They do not corrode nor allow sediment buildup over time. They can withstand freezing temperatures much better than copper. Since they are flexible, they can expand up to eight times their size! This means they aren't likely to burst easily when water expands as it freezes.

PEX tubes have also become a popular choice because of their affordability. They are 20% to 40% cheaper than copper pipes. They are also easy to work with and provide plumbers with an easier way of connecting the pipes instead of just soldering them together. The crimp-ring and push-fit connectors make these pipes very convenient to install.

So, while copper pipes are still used for plumbing, homeowners now have another equally excellent choice when it comes to the material used for their pipe systems.

What is the life expectancy of copper plumbing?

Copper pipes are one of the leading materials used for our water supply system because of their long life expectancy. With proper maintenance, they can last anywhere between 20 to 50 years or even longer.

However, copper pipes aren't created equal. Their specific type will give you a better idea of how long they will last.

Types of Copper Pipes

Here are the three different kinds of copper pipes:

M Type

These are the thinnest and lightest among all copper pipes. They are also the easiest to work with and the most affordable option. However, they are not as durable as the other types of copper pipes. They have the shortest life expectancy, which should be around 20 to 50 years.

L Type

These are thicker and more reliable than M Type copper pipes. They can be used outdoors and underground. This type is best used for residential settings and can last for 50 years under ideal conditions.

K Type

These are the thickest and most durable copper pipes and also the most expensive among the three. Because of their price, they aren't practical to use for residential purposes. They are better used for commercial buildings where they are expected to last for more than 50 years, making them worth the investment.

Environmental Effects On Copper

Environmental conditions also play a big part in determining the life expectancy of copper pipes.

When piping or repiping your home, check the water if there's a high content of sediments, level of acidity, and presence of chloramines. Check also if there are improper connections of your electrical wirings and if your copper pipes are in contact with other metals. All of these factors can cause the weakening of your pipes.

It is also important that you ensure the use of controlled water pressure in your home and have a plumber check your pipe system regularly at least once every five to ten years. Check if there are any leaks, cracks, discoloration, or corrosion. If you notice these signs, call your plumber immediately.

Final Thoughts

Go ahead and use Flex Seal, expanding foam, or silicone sealant to fix those gaps and cracks between your wall and copper pipes. They are so easy to apply and are long-lasting, too. With a little effort, you'll have peace of mind knowing that you've sealed off your home from bugs, water, air, and moisture.

Visit these links for some related reading:

How To Keep Copper Pipes Shiny? [Plus Natural Methods & Oxidation Prevention]

How Long Do Copper Pipes Last And When To Replace Them?