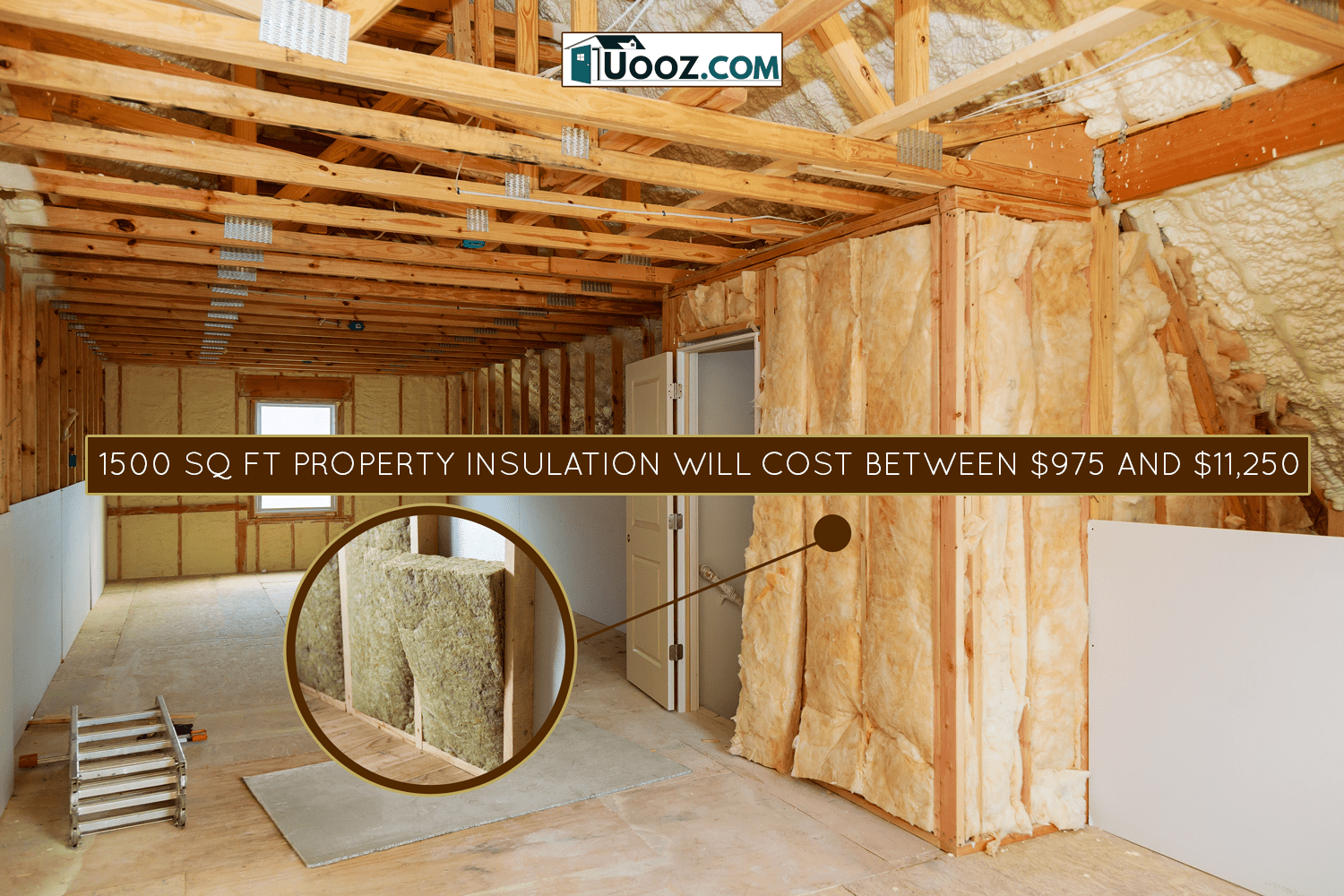

Having a 1,500-square-foot property may have you wondering how much it costs to insulate such a huge space. That's why we searched for answers, and here is what we gathered.

A 1,500-square-foot property will cost its owners between $975 and $11,250 to insulate. Be aware that the price of insulation might change and can go up or down depending on whether it is installed before or after the house is built, the material you use, and the type of insulation.

Keep reading as we give you information on how much insulation costs per square foot. We'll also discuss the types of insulation that are best to use in specific portions of your house, i.e., your garage, walls, basement, roof, and attic. We'll also cover what factors to consider to make your insulation investment worth its cost.

How Much Does An Insulation Cost Per Square Foot?

To give you an idea of how much money you need to prepare, here is a list of insulation costs based on:

- Type Of Insulation

- Insulation Material

- Installation Scenario

Cost Based On The Type Of Insulation

The table below shows the price per board foot of different types of insulation. Each insulation provides a range of R-values from 3 to 8.

| Insulation Type | Cost Per Board Foot |

| Batting Insulation | $0.30 – $1.50 |

| Blown-in Insulation | $1 – $2 |

| Spray Foam Insulation | $0.50 – $2 |

| Rigid Board Insulation | $0.25 – $1 |

Batting Insulation

It is the most affordable method of insulating a house. Batts are produced using long rolls of fabric that are covered with paper or a metallic barrier. Between joists is where they can be put. They are therefore a fantastic option for walls, attics, and ceilings.

Existing walls cannot be expanded upon without fully opening them. Because of this, they are typically put in new buildings, renovations, and open spaces.

Blown-In

Rockwool, cellulose, or fiberglass are possible materials for it. This type of insulation is quite simple to add and can be done in most places. Although, it is not added to vertical parts when buildings are being constructed since it attempts to fly around but can be blasted into already-existing walls. It can be installed at any moment to open areas like attic floors.

Spray Foam

Typically, this consists of liquid insulation that is sprayed into small fissures on surfaces like roof decks or attic flooring. The foam expands to fill the space upon touch.

Although it can be used with existing walls, compared to loose fill, it can be highly expensive. When raised to the proper thickness, it performs better as insulation.

Rigid Board

This material is akin to wood fiber or cork insulation. It is uncommon and frequently inappropriate. Usually, it is added to ceilings, some basement spaces, and certain attic spaces that require an additional layer of insulation.

These materials can't be utilized outside because they are typically not water-resistant. Use this material to give an interior room an extra layer of soundproofing.

Cost Based On The Insulation Material

Here is a table of costs per square foot based on the insulation material you want to use.

| Insulation Material | Cost Per Square Foot |

|

Cellulose |

$0.60 to $2.30 |

|

Fiberglass |

$0.40 to $1.50 |

|

Rockwool |

$1.40 to $4 |

|

Blue Jean |

$1.15 to $1.75 |

|

Polystyrene |

$1 to $15 |

|

Sheep Wool |

$1.50 to $2.80 |

Cellulose

Almost mainly applied as loose fill, cellulose insulation is blown into existing wall cavities. It typically comes in the form of a wet spray that adheres to the walls and sticks together.

Fiberglass

One of the earliest and most well-liked varieties is this one. It can be used in the majority of interior areas and is available in batts and loose-fill. When installing the batts in new construction, it is typical to utilize them in wall cavities and between floors.

It is frequently used in basement ceilings and attics of older structures. The loose fill is typically used in attics and crawl spaces because it cannot be used inside of existing walls.

Rockwool

Recycled furnace slag is spun into fibers to create rockwool insulation. Similar to fiberglass, it is produced in batts or loose fill. Although it is somewhat more expensive, it insulates better than fiberglass.

Because rockwool contains silica, only professionals with the necessary skills and can take the necessary safety measures to contain the dust should install it.

Blue Jean

Blue jean insulation, which is manufactured from recycled blue jeans, is a safer alternative to fiberglass batting that is also more environmentally friendly. It is simpler for DIYers to use since it does not include tiny glass particles like fiberglass.

Polystyrene

Foam boards and spray-on insulation both employ polystyrene insulation as a base. While spray foam is used to fill wall cavities or under attic floors, foam board is utilized to cover the exteriors of structures [under roof shingles or siding].

Sheep Wool

Typically, batts contain this type. Moisture does not affect this natural substance, which performs better insulation than other materials. For do-it-yourself installers, it is simple to use and carries no significant dangers to one's health.

The majority of insulation types are more expensive than this material. Finding a supplier for this material may be more difficult due to its limited availability.

Cost Based On The Installation Scenario

|

Installation Type |

Cost Per Square Foot |

|

Applied To Existing Walls |

$1.75 – $7.50 |

|

New Building Construction |

$0.65 – $6.50 |

Installation In Existing Walls

Insulation can be added to walls without completely removing the drywall and rebuilding them. by using blown-in or spray foam insulation.

An easier and more affordable insulating technique is blown-in insulation. Wet-spray cellulose is blown into the structure in this instance through a series of tiny external holes.

Installing spray foam is more expensive and more complicated, but it might produce superior benefits. Multiple holes must be made in the walls, and the subsequent repairs will cost more money.

New Construction Installation

Different kinds are suitable for new construction. The most popular method is to insulate open spaces with spray foam or loose-fill and utilize batt insulation on the walls and ceilings.

Before it is walled, you can also use several types of rigid insulation boards outside. Multiple varieties are frequently used in new buildings, but you can alternatively use only one to reduce costs.

How Much Does It Cost To Insulate Different Locations Of Your Home?

The area of your home that requires insulation can also have a significant impact on the overall cost. A house should be completely insulated from top to bottom in these places to be as energy-efficient as feasible:

- Garage

- Basement

- Attic

- Roof

- Walls

Garage

Without including the garage door, a typical two-car garage will cost insulation prices ranging from $0.50 to $1.25 per square foot. Rarely are garages initially insulated, and many homeowners only do so if they complete the space or build a living area above it.

To lower the energy expenses associated with heat loss, some individuals also insulate garages.

Basement

Insulating a basement typically costs between $1.50 and $2.50 per square foot. Since the ground around the space helps keep it cool in the summer and warm in the winter, a basement typically does not require as much insulation as the rest of the house.

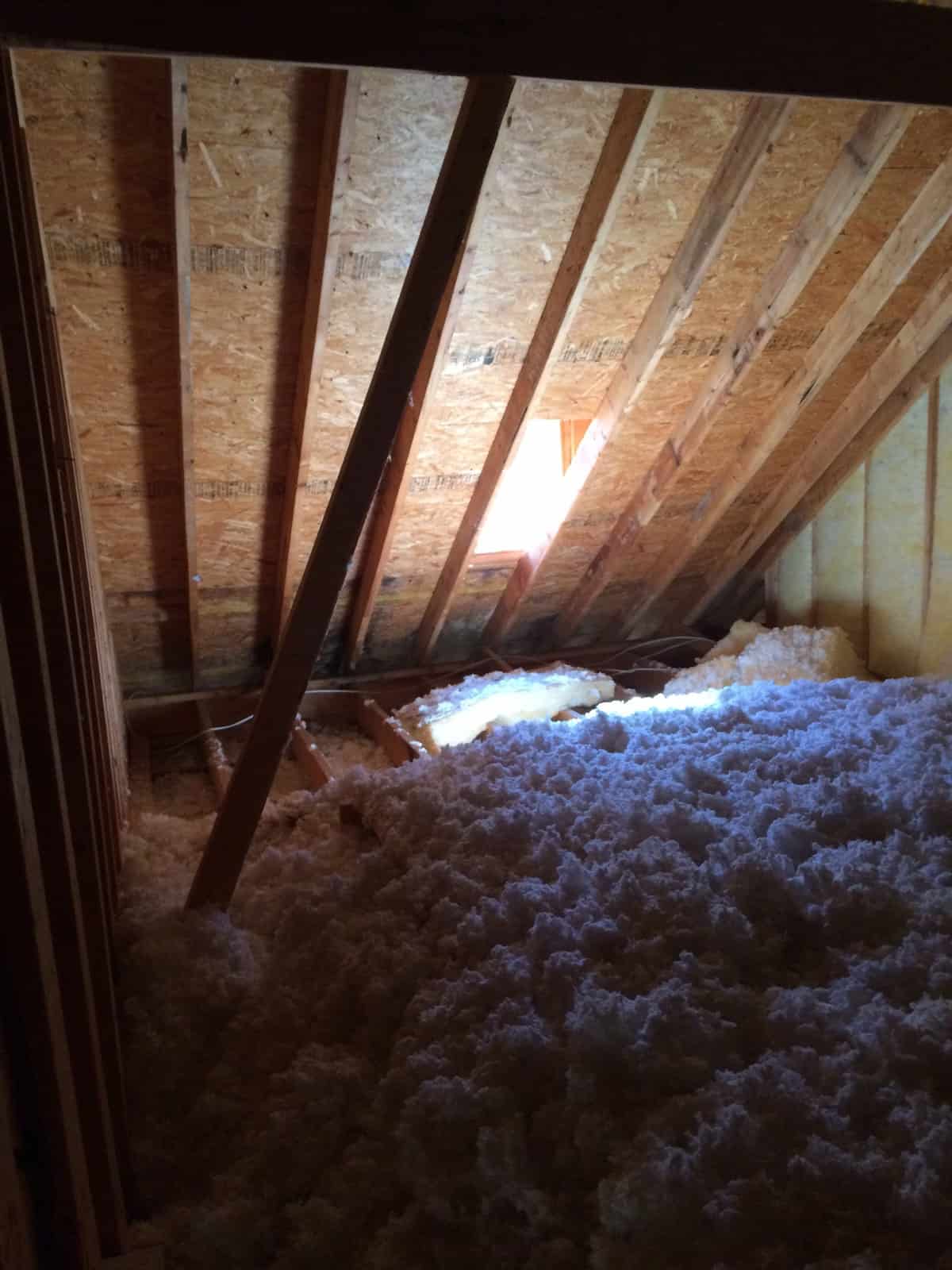

Attic

Insulating an attic typically costs between $1,500 and $6,000. The most crucial area of your house to insulate is the attic. Since heat rises, many homes have twice the insulation in their main walls to prevent the loss of warm air that is rising.

Batt or blown-in insulation is the next most popular material to employ in attics after spray insulation foam.

Roof

The typical price range for roof insulation is between $1,500 and $4,500. A specialist can lay rigid foam board insulation beneath the roofing for new homes. For older houses, the rafters might be covered with batting or spray foam.

Walls

The price of wall insulation will be between $1 and $4 per square foot. The most popular type of insulation is wall insulation, which is commonly installed as mineral wool or fiberglass batting inserted between the wall studs. Spray foam or rigid board insulation can be installed beneath the outer siding of newly built homes.

What Factors Should You Consider To Make Your Investment Worth Its Cost?

Here are some of the things you need to look into if you want to get the most out of your investment.

- The energy standards for new structures and dwellings in your area could be governed by local, state, or federal codes. In most cases, they dictate certain levels or R-values for the insulation in each room of your house. Make sure your contractor is aware of and abiding by the regulations in your area if you're building a new house.

- Along with installing insulation, you can also make several other energy-related improvements to your home that will improve its overall energy performance. These will improve your home's overall thermal efficiency and can qualify you for regional or national incentives.

- Today, a large number of insulation producers provide environmentally friendly products that either partially or completely consist of recycled and/or biodegradable materials.

In Closing

If you are working with a contractor, be sure to receive at least three estimates, just as with any home improvement project. This enables you to determine the project's true costs and the price that best fits your budget.

If you're into DIY, you can check out these posts: