Are you working on a concrete driveway for your garage, and you’d like to know the ideal space between concrete expansion joints? You’ve come to the right place, for we have researched this question, and we have the answer for you.

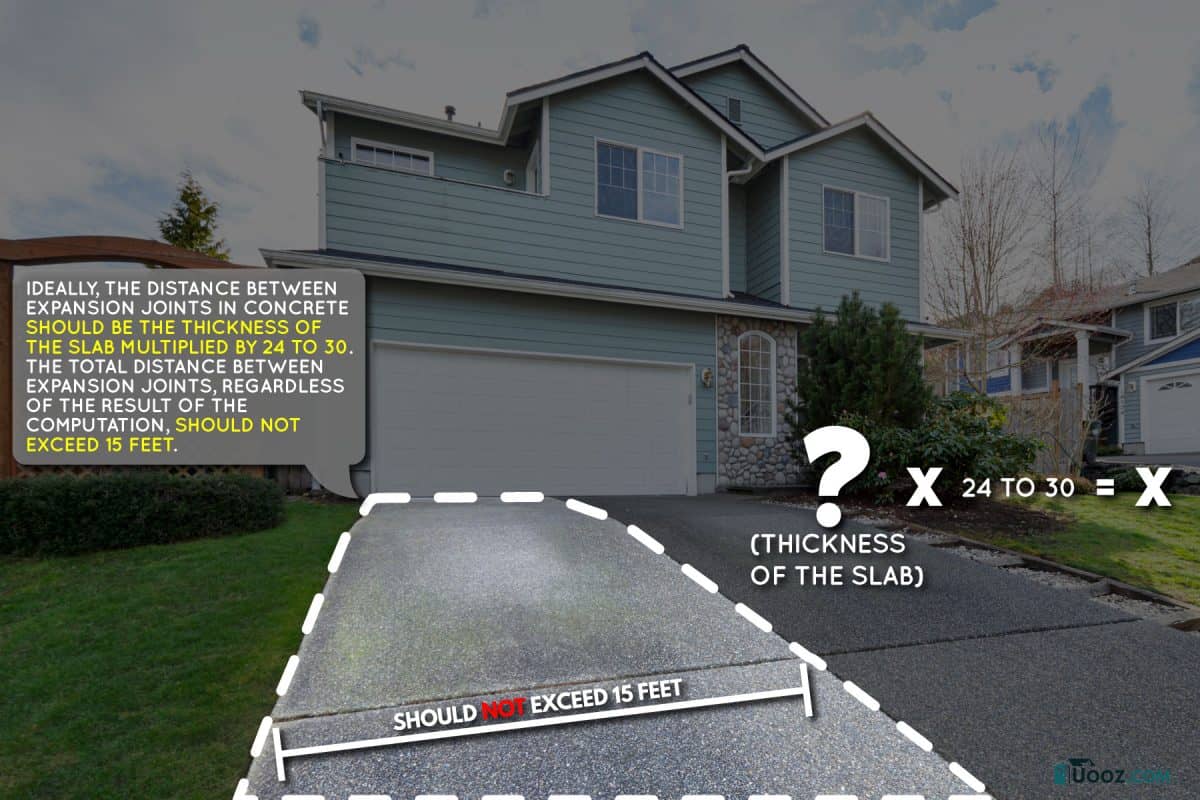

Ideally, the distance between expansion joints in concrete should be the thickness of the slab multiplied by 24 to 30. The total distance between expansion joints, regardless of the result of the computation, should not exceed 15 feet.

Let’s talk more about concrete expansion joints in the succeeding sections. Learn more about why an expansion joint is so important below.

Read on!

Is it necessary to have an expansion joint in concrete?

Concrete starts as a mass of fluid material that can flow into any shaped mold. However, as concrete slowly dries and sets, it loses mass as it loses water. This drop in volume causes the concrete to shrink.

While concrete is a very strong material when it comes to resisting compressive forces, its ability to withstand tensile forces is only around 15% of its compressive strength. The average compressive strength of concrete is between 2500 PSI to 4,000 PSI. The tensile strength ranges between a mere 300 to 700 PSI.

What this means is that while concrete can carry large amounts of weight, it is weak against forces that pull at it from opposite directions. These are tensile forces.

When concrete dries and loses mass, concrete surfaces become stuck in adjacent surfaces. Thus, shrinkage creates tensile forces, and if the tensile force is greater than what the concrete can withstand, then the concrete will crack.

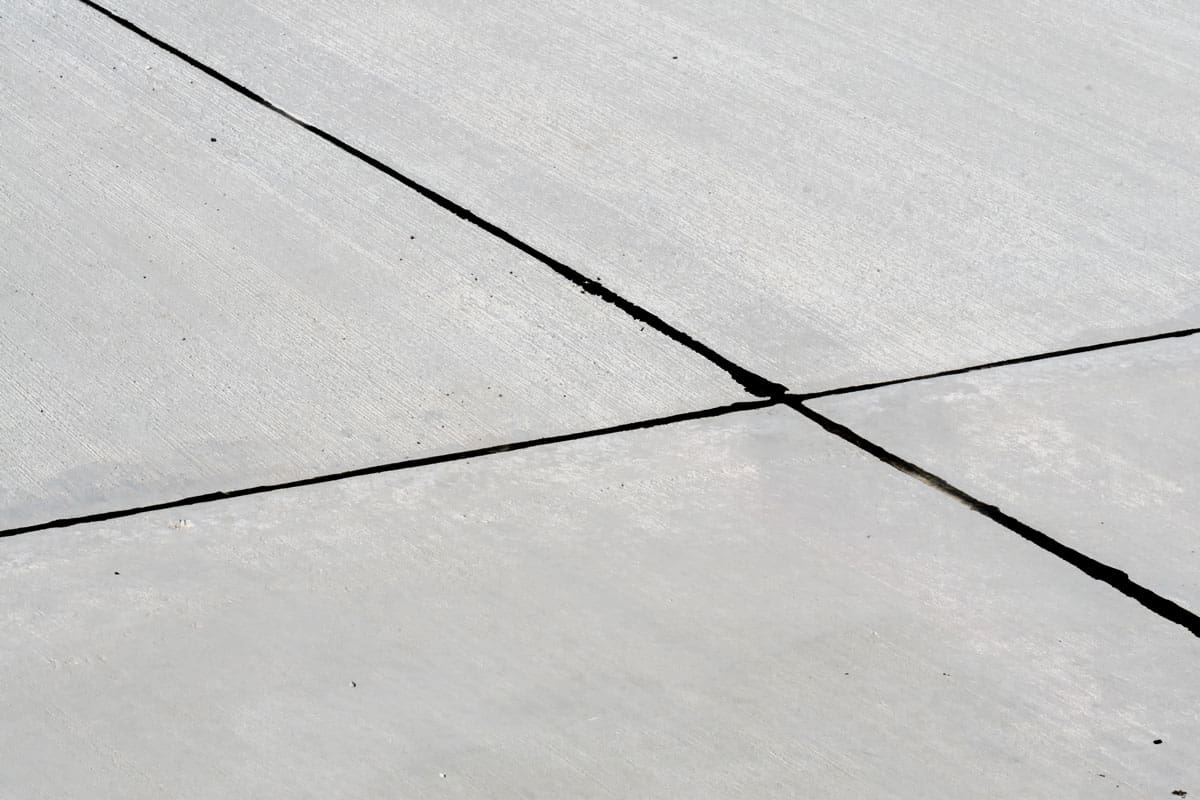

Expansion joints, also called control joints or contraction joints, are added to concrete slabs to create a location that is smaller or narrower than the rest of the concrete slab. The narrower control joint creates a weaker area that forces the crack to occur there. This directs the crack to happen below the surface of the concrete, giving the concrete slab a clean-looking surface.

This is an acceptable alternative to cracks appearing randomly on the surface. Additionally, expansion joints also allow the concrete to expand and contract with the changing of the seasons.

What is the size of the expansion joints?

There are many ways of mitigating tensile forces in concrete. One of the most common methods of adding an expansion joint into concrete is by cutting the slab of concrete.

A cut is done several hours after you finish pouring concrete.

The cut should have a minimum depth that is a quarter of the total thickness of the concrete. Thus, if the concrete is four inches thick, the cut should be at least an inch deep to become effective.

Is it possible to have no joints in concrete?

Yes, it is possible.

Concrete joints are important for most concrete applications. However, some concrete mixes and setting techniques can eliminate the need for joints. These techniques make use of a different ways to redirect the stress from expansion and compression.

Concrete With Synthetic Fiber

Special synthetic fibers made from polypropylene, polyethylene, and nylon can be combined with concrete mixed with standard ratios. The result is a special type of concrete that reduces the incidence of settlement cracks. Moreover, the presence of synthetic fibers reduces the number of cracks that appear due to shrinkage during curing.

The synthetic fibers in the concrete effectively reduce the effects of tensile forces that develop in the concrete during and after curing. Synthetic fibers act as reinforcement against tensile forces.

This is a special concrete mix that you can use. However, you will need concrete experts to install this type of concrete in your driveway.

Reducing The Size Of Cracks

A technique of reinforcing concrete can significantly reduce the size of cracks, making them unnoticeable. The presence of steel in the concrete resists tensile forces that concrete is weak against. The installation of the reinforcing steel two inches from the surface of the concrete slab will reduce the size of the cracks.

Crack Inducer Tubes

Crack inducer tubes are specially designed PVC tubes that support a weakened area, brining the cracks to their location.

These tubes serve as expansion/shrinkage pipes that absorb tensile forces, preventing the formation of cracks on the concrete slab's surface. This allows you to skip the installation of expansion joints on your concrete driveway.

While this technique is fairly new, you can check with local contractors in your area if they have the proficiency to install this type of concrete for your home.

Shrinkage Compensating Concrete

This is a type of concrete that can eliminate the appearance of tensile forces during the curing stage. This concrete’s special formula reduces the shrinkage of the concrete. With the reduction in shrinkage, the tensile forces that cause cracks in concrete will be low enough for the concrete to resist them.

A concrete mix is treated with chemical additives or expansive cement. The result is concrete than expands during curing. Suppose the rate of expansion of the end product is equivalent to the rate of compression during curing. In that case, the mixture will effectively eliminate expansion and the production of tensile stress on concrete.

Without the tensile forces during curing, the concrete slab no longer needs an expansion joint.

The downside of this concrete is that the mixture must be accurate. Inaccurate mixing of the components will cause the expansion rate to become greater than the rate of compression. This imbalance will cause the product to become weak against compressive forces.

Thus, only experts in mixing this type of concrete should handle its installation.

How far apart should expansion joints be in concrete?

When installing a concrete slab for your driveway, it is important to measure the thickness of the slab. The thickness will allow you to compute the distance of the expansion joints.

Ideally, expansion joints should not be less than 10 feet apart and should not be more than 15 feet away from each other.

Some contractors measure the thickness of the concrete slab in inches, then multiply the total thickness of the concrete by 2 or 3. Once you get the total, you drop the “inches” unit and replace it with feet.

For example, if you have a concrete slab that has a thickness of 4 inches and you decide to have expansion joints that are closer to each other. You multiply the thickness by 2, giving you 8.

However, instead of 8 inches, you replace inches with feet. Thus, the distance between the joints in this example will be 8 feet.

Do you need to caulk expansion joints?

Yes.

Caulking the joints in your concrete is important because it prevents water from filling the joints and causing damage. Water can erode your concrete and cause damage over time.

Moreover, since caulking prevents water from getting into the space of the expansion joint, caulking effectively prevents concrete damage due to water freezing in the winter months.

Water expands when it freezes. This causes the water in the joints to force its way into the pores of the concrete as it freezes and expands, cracking the concrete.

Leaving the expansion joint open will also cause the weed to grow there. The roots of weeds can force their way into the concrete and weaken it, eventually damaging it.

Filling And Caulking

Keep in mind that caulking the expansion joint is not the same as filling the expansion joints.

The filling is normally done with rigid materials that can end up being too hard and stiff for the concrete slab. This can result in restricting the concrete slab when it needs to expand or contract.

Caulking, on the other hand, is done with a flexible material. The flexibility of caulk gives the concrete the room it needs to expand and contract.

How to caulk concrete expansion joints?

- Use a rigid brush to loosen the debris inside the expansion joints.

- Use a powerful vacuum to get the dirt and debris out of the expansion joints.

- Apply masking tape along the edge of the expansion joint. The edge of the masking tape determines the edge of the caulk. Keep in mind that uneven application of the masking tape will lead to an uneven caulk.

This scrub brush is available on Amazon through this link.

Filling The Joint

- Load a concrete or polyurethane caulk into your caulk gun.

- Trim the caulk cylinder to have a tip that is slightly wider than the space between the masking tape.

- Apply the caulk into a foot or two of the expansion joint’s length. The tip of the caulk gun should face ahead of the gap. This will cause the tip of the caulk cylinder to push the caulk under it as you slide the caulk gun forward.

- Tool the caulk to give it a slight concave.

-

- Spray a very thin layer of soapy water over the surface of the caulk.

- Use your finger to tool the caulk, giving it a smooth and concave surface.

- Sprinkle a thick layer of very fine silica sand over the caulk after tooling.

- Repeat Steps 3 to 5 until you complete filling the joint.

- Leave the caulk to dry and cure.

DAP sealant is available on Amazon through this link.

Silica sand is available on Amazon through this link.

Conclusion

The distance between the expansion joints in your concrete should not be less than 10 feet and not more than 15 feet. Expansion joints are essential to maintaining a smooth concrete surface over time, by allowing support while shifting to reduce cracking.

If you enjoyed reading this article, you might find the articles below equally enjoyable to read:

How To Keep A Garage Door From Sticking To A Concrete Floor?

Best Epoxy Coating Products For Concrete Floors [7 Fantastic Choices]