Corrosion often causes pipe joint failure, and plumbing flux can help you with that. However, you might be unsure whether it is still in good condition. So you ask, does plumbing flux go bad? We did the research, and here's what we found.

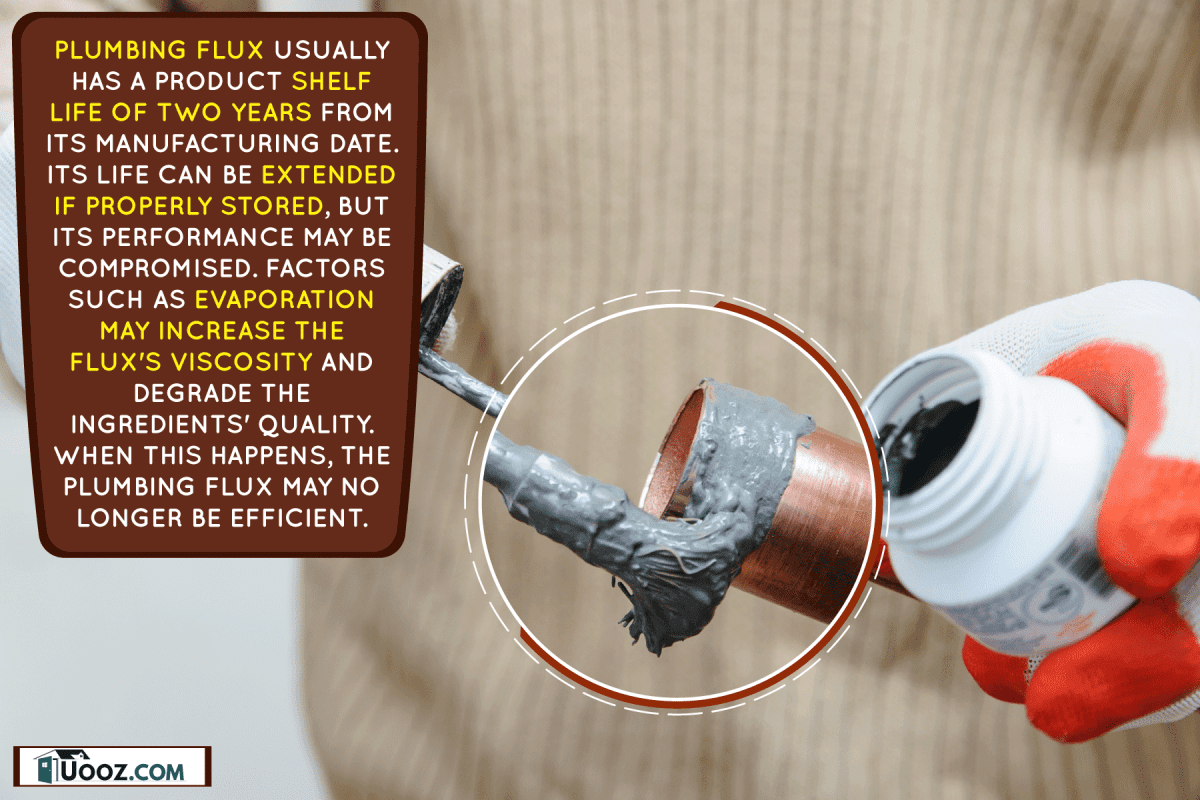

Plumbing flux usually has a product shelf life of two years from its manufacturing date. Its life can be extended if properly stored, but its performance could be compromised. Evaporation might increase the flux's viscosity and degrade the ingredients' quality. When this happens, the plumbing flux may no longer be efficient.

Now that you have an idea of the shelf life of the plumbing flux, let’s talk more about the functions of plumbing flux and how to use it. This guide will help in future projects and avoid unnecessary errors in plumbing work.

How Does Flux Go Bad?

A typical plumbing flux has a two-year shelf life, but you can extend this with proper product handling and storage. Consecutively, the quality could be compromised for the following reasons:

- Leaving the tub open exposes the product to the air and will encourage evaporation. When this happens, the product viscosity and consistency increase, making application difficult.

- Ingredients from previous soldering activities might contaminate plumbing flux. Certain ingredients affect the overall quality of the product.

- Exposing the plumbing flux to extremely high or low temperatures can greatly affect its quality.

How To Know The Flux Is Bad?

Once the flux has become thick or hard to spread, it may have already gone off. One tell-tale sign would be a change in its color. Flux is typically opaque white and might turn brown or stained if contaminated.

What Happens When I Used Expired Plumbing Flux?

Once the plumbing flux has expired, its ability to clean and oxidize metal surfaces degrades. As a result, pipe connections will not properly bind together and have poor electrical connectivity.

Plumbing Flux: A Soderers' Partner

Plumbing flux is a widely used acidic paste applied to a soldered joint. Due to its acidic nature, it not only cleans the pipe but also draws flame to it. This forms a water-tight seal that prevents future leaks and damage.

The main function of the plumbing flux is to help the solder “flow” around the fitting and form a seal. A high-quality plumbing flux cleans the surfaces and ensures good solder flow. It prepares the metal joint to promote effective soldering, and it protects the surface from corrosion and other contaminants.

How Does Flux Work?

A soft metal bonding called solder bonds two compatible metals together. To be effective, metal surfaces must be clean and free of any dirt and oxides, as these could be a problem during bonding.

Plumbing flux is a product applied to the area where the bonding is made. When melted, the flux spreads to the surface, clears off dirt, and forms a layer to prevent oxides from forming. The high temperature during soldering comes with high oxidation as well. The flux, with its acid, reacts with the oxide layer and leaves a primed and smooth surface.

Wet Vs. Dry Joint

A wet joint means there is an effective application of flux, which allows the solder to flow on the metal surface. A dry joint is where the flux does not flow, thus creating a bad joint.

To avoid a dry joint, you must apply a quality plumbing flux. The product has a surfactant or a wetting ingredient that allows the solder to flow through the surface, creating a good and conductive bond.

Types Of Plumbing Flux

There are different types of plumbing flux available. Having an idea of the advantage and disadvantages of each flux can help you choose the right one for your project.

Water Soluble Flux

Water soluble flux is good for a wide range of metals and solders. These types of fluxes clean metal surfaces and allow effective solder flow. However, they can char easily, which leads to discoloration. Charring does not affect the soldering of the joint; you can easily rinse it away with water.

Check out this LA-CO Walter Flux on Amazon.

ASTM Compliant Flux

ASTM sets standards for processes and equipment in various industries. Although compliance with ASTM is not mandatory to the law, following the standard ensures the best performance.

ASTM B-813 refers to the standard specific to copper plumbing. This type is less corrosive and water-soluble. They have lower levels of active ingredients to fight away corrosion.

As a result, the cleaning ability and solder flow may be compromised, and charring is usually expected with this flux. Use ASTM B-813 compliant flux for areas that are strictly observing the standards.

Check out this C-Flux on Amazon.

Petroleum-based (or Petrolatum) Flux

This flux has high levels of active ingredients and acid content, which poses an environmental concern. It shows less efficiency when it comes to solder flow, and since they are water-insoluble, the residue is impossible to flush with water.

Nevertheless, they are highly resistant to overheating and do not cause discoloration. Several industries use this type of flux for connections subjected to high temperatures.

Click here to check out the SRA Rosin Paste Flux on Amazon.

How To Use Plumbing Flux

With several options for plumbing flux, acid flux is the best when joining copper pipes. These can remove large areas of oxidation which results in stronger soldering work.

Here are the steps to prepare the pipe for soldering and apply flux correctly.

Prepare The Pipes

Clean any dirt from all parts of the pipes and fittings that will be soldered. Make sure to have a smooth surface to allow the solder to adhere tightly and securely.

Then, clean the area thoroughly to ensure that even the parts of overlap between the pipes and fittings are ready to solder. You can use 120-grit sandpaper or grade-1 steel wool to keep the pipes intact while removing dirt and grime.

Coat Pipe Fittings And Areas To Be Joined

Ensure to apply plumbing flux evenly. Some brands include a brush for easy application of the product. Do not over-apply surfaces you don’t intend to solder. Solder flows to wherever flux is applied so overapplying might not be a great idea.

Heat The Pipe Connection

Bring the two pieces together and heat the pipe connection using a soldering torch. Heat the parts for 30 seconds, then press the soldering reel. Once bubbles form along the seam, your connection is ready.

Solder Paste Vs. Plumbing Flux

Both products bond compatible metals together. Solder paste glues the two pipe connections while flux acts like a preparatory ingredient added before or with the solder paste to achieve smoother and more solid work.

It is important to apply flux as it would be impossible to adhere two pieces together with solder paste alone. Flux is a non-negotiable ingredient during soldering to achieve a metallurgic bond. This ensures the integrity and strength of the soldered joint against damage.

Tips On How To Use Flux Effectively

Soldering can be tricky and requires a lot of patience to achieve the desired result. However, if done correctly, it can be a walk in the park. Here are some of the tricks which might help you in your project.

- Select the best flux for your soldering works. This helps you maximize the product and ensures it is appropriate for the material.

- Make sure that the surfaces are clean as possible before beginning any soldering works. It will be difficult to work with a dirty pipe and it will give you low-quality results.

- Start by applying small amounts of flux until both pipe surfaces are coated. Avoid overapplication as this could cause excessive spattering. Then, join them together before heating.

- Heat the surfaces evenly. Uneven heating leads to poor solder flow, while overdoing it may damage and cause decomposition of the flux.

To Wrap It Up

Although indicated with a two-year shelf-life, you can easily extend the expiration of a plumbing flux with proper handling and storage. Just remember to keep the lid closed and avoid contamination of the product. If the flux is hard to spread and the color has turned yellow or brown, it may be time to throw it away and buy a new one.

If you found this post insightful, be sure to check these other posts:

How To Install Range Hood Without Cabinet