It is common to face problems while using air compressors. An air compressor failing to turn on can stem from a lot of reasons. And most of the time, there are a handful of solutions you can implement to get it back to running yourself without needing to take it to a repair shop. We have looked up those solutions and compiled them here for you, so let's take a look.

The first step is identifying the problem. If your air compressor isn't turning on all of a sudden, you should do the following things:

- Check if there's a lack of power. Check if you plugged in the power cord correctly. Also, make sure the power switch is on. If your compressor operates on oil, make sure there's enough oil to run it.

- Check the tank gauge to see the pressure in the compressor tank. Some applications require more pressure than is available. You can fix this by changing the power switch with the lower cut-in.

- Empty the gas tank and check if the pressure switch is tripping. You must hear a click sound after powering on the compressor.

- See if there's a humming sound coming from the motor. If yes, then press the compressor reset button.

- Ensure that the unloader valve is working correctly after the machine starts. If not, your compressor will fail to turn on the next time.

If the answer is not enough for you, we will explain these solutions further with the causes. If you want to maintain your air compressor in the long run, you must understand how to fix these issues. We will also take a look at some tips to keep your air compressor more durable. So, keep reading.

What Can Cause an Air Compressor Not To Start?

The most common problems you could be facing are lack of power source, check valve failure or a bad pressure switch. You can perform these solutions yourself, provided all safety requirements come into consideration. Your air compressor might be failing to turn on because:

Unplugged From the Power Source

As simple as it sounds, it is a pervasive problem. Since air compressors require a lot of power to run efficiently, it is best to check whether you plugged it into the power source correctly or not.

It Has Run Out of Oil

It is another common problem relating to the power source. If your air compressor uses fuel instead of electricity, you should always check whether the tank is full or at least enough oil to get the air compressor running.

The Power Switch Is Experiencing Problems

If the motor of your air compressor fails to power on when you flip the switch, it must be an issue with the automatic run sensor. It is an inner circuit problem and can often get resolved by adjusting the pressure.

If the machine runs for prolonged periods, the power switch can automatically cut the power off to avoid overheating. However, you should run some tests before drawing any conclusions.

The Pressure Switch Is Experiencing Problems

If you break the pressure switch on an air compressor, you might be surprised by the underlying complexities. Any old replacement switch will not solve the problem due to all the connecting points of the manifold.

To fix the problem, you will need a button that connects with all 5 points of the compressor. It includes sockets for the pressure relief valve, the air tank gauge, the compressor tank, and the quick coupling.

Before you buy a new pressure switch and manifold, take note of the following details on the old switch, it must match with the compressor:

- The number of ports on your pressure switch and manifold.

- The voltage of the original pressure switch.

- The cut-in and cut-out settings on the old pressure switch.

- The hookup of the unloader valve.

Be careful to properly thread the ports of the new manifold onto their corresponding parts of your air.

Blown Fuse or Tripped Breaker

When an air compressor is causing an electrical fault, a fuse will blow and shut down the breaker system. There is no electricity going to your air compressor. Some air compressors have reset switches.

Others will have in-line fuses that need checking. To find them follow the line of power from the air compressor back to the outlet. If you find a blown-up fuse or tripped breaker go ahead and either replace the fuse or reset the breaker.

Potential issues that cause electrical problems include:

- An overloaded or failing motor

- A bad start capacitor

- A blown-out fuse switch

Tips to Maintain an Air Compressor

Understanding the root of issues and knowing how to fix them is a start. But what's even better is maintaining your air compressor to be more durable in the long run. Here are some tips that can help you make that happen.

Don't Leave the Cord Plugged In

Always make sure that you disconnect your air compressor from the power source and turn off the power button after using it. In the unlikely event that the gas engine leaks gas, the machine will be running non-stop and won't be able to turn on when needed.

Take Care of the Internals

Long-term usage will have an impact on the internal parts of the compressor. You should check the internals regularly and see if something needs maintenance.

Use It Periodically

Make sure you don't run the machine for too long. Prolonged usage can overheat the engine and even lead to an explosion. If you're not using it professionally, don't use it for too long. You should always let the machine air condition before another use.

How Do You Know if the Pressure Switch Is Faulty on an Air Compressor?

If, for example, your air compressor cuts out at 120 PSI, and now it has started shutting off consistently at 95 PSI, that would point to the pressure switch having a problem.

Check the pressure switch via a multimeter to determine if, when the air compressor has shut off at 95 PSI, that power is not still passing the pressure switch to the motor circuit.

One side of the switch will be the power supply side, and the other will be the load or motor side. When the compressor has cut off, you need to know if the power is still flowing from the power supply side to the motor side.

If the power is not flowing, meaning the pressure switch has tripped off at 95 PSI. Since it is supposed to trip off at 120 PSI, it might be unusable. If you want some visual help, here's a YouTube video:

What Causes an Air Compressor To Trip?

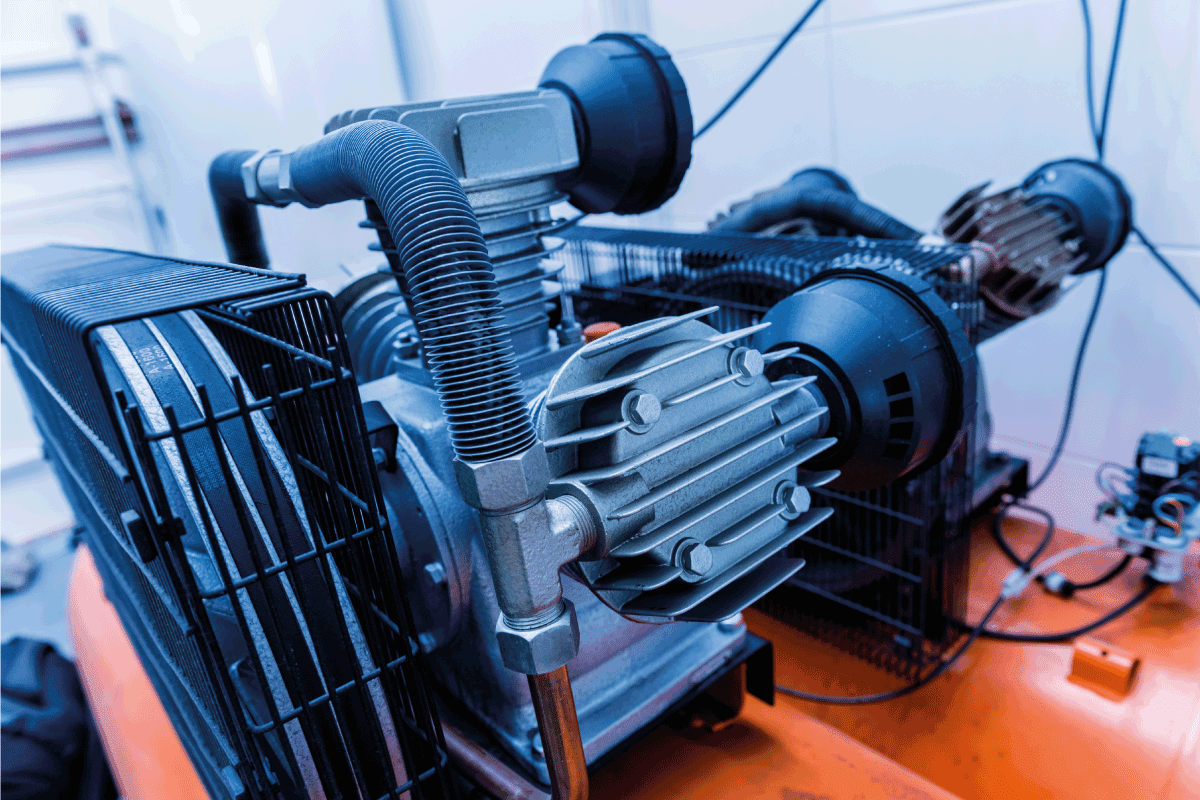

In most cases, the motor pulls too much amperage - but before diving into the electrical circuit. In this situation, you can start by inspecting the mechanical parts.

In some cases, the pump may be stiff or locked up. You may also inspect the bleeder or loader valve. If you find any damages to either valve, a simple replacement can get it working again.

Moving the compressor may also identify a weak breaker. If the breaker trips on one 15 amp breaker but not the other, the tripped one may be old and worn.

Experienced users would recommend placing the compressor back in its original location.

How Do You Reset an Air Compressor?

To reset an air compressor, you need to:

- Remove the screws from the plastic shroud on top of the compressor near the air outlet valve. Lift the hood from the compressor to reveal the upper and lower pressure limiter adjustment screws.

- Turn the compressor on and allow it to charge. Make a note of the pressure on the pressure gauge when the compressor turns off. Pull the air release valve to release pressure from the tank.

- Adjust the lower limiter control screw by turning it clockwise to increase the pressure or counterclockwise to decrease it.

- Screw the hood back on. Your compressor has reset to factory settings.

Where Is the Unloader Valve on an Air Compressor?

A smaller air compressor has its unloader valve in the pressure switch. A larger air compressor will have its valve located near the compressor gauge.

Final Takeaway

Air compressors have many uses. When it's not in working order, it can be tough to diagnose the problem. However, you'll fare better if you go in with an idea of what part could be causing you trouble. We hope you found the information above helpful.

Before you go, do you own Craftsman power tools? If they aren't in working order, you might want to see if it has a warranty. To learn more, check out our post, "Does Craftsman Warranty Its Power Tools?"

Are you planning on using a caulk gun for a project? You might want to inspect it to make sure it's working! If it isn't, check out our post, "Caulking Gun Not Working - What To Do?"

Until next time!